Your hand will not slide easily up and over this abrupt shoulder. So,

just take that handy X-acto knife and cut in a neat little bevel, thusly:

Your hand will not slide easily up and over this abrupt shoulder. So,

just take that handy X-acto knife and cut in a neat little bevel, thusly:AVERY SQUEEZER MODS

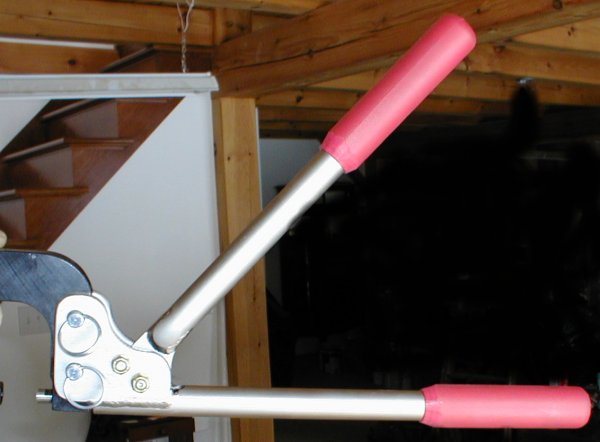

Like all good hand tools, you get what you pay for. That's why what might be considered to be vintage hand tools to some are just Grandpa's reliable old tools. It's also why it's a good idea to try out multiple brands of tools and to feel free to modify a good tool to be perfect for you.

This page is devoted to describing the modifications I performed to make the Avery hand squeezer even better.

I used the Avery, Cleaveland, and Tatco hand rivet squeezers when I attended the RV Tail Building program at Alexander Technical Center in Griffin, GA.

Overall, I probably liked the Tatco better. I liked its smaller diameter handle and the way it fit my hand easily, especially when sitting down doing one-handed dimpling of small parts. I also liked its stronger return spring, again especially for one-handed use.

However, the Avery is a good squeezer, and I particularly liked the fact that it uses the interchangeable pneumatic squeezer yokes, of which I have several.

So, I made some modifications that I think will improve its use for me, and perhaps for you, too.

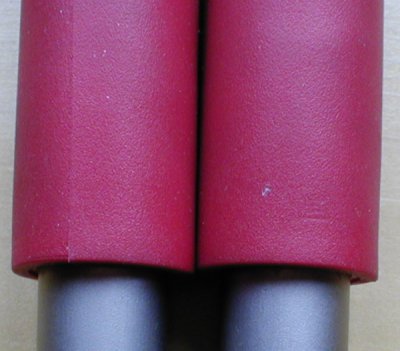

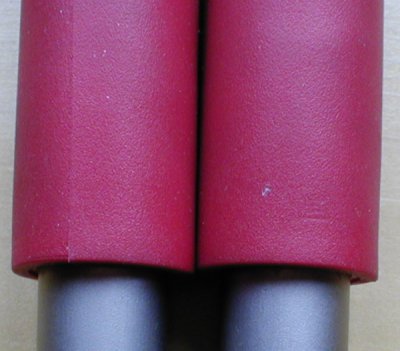

The first mod I made was to taper the ends of the grips. The Avery grips are nice and thick, but this presents a bit of a problem when you start your squeeze with your hand near the head end, then slide your hand out toward the ends of the handles for more power to finish the squeeze. This pic shows what a steep transition it is from the handle to the grip:

Your hand will not slide easily up and over this abrupt shoulder. So,

just take that handy X-acto knife and cut in a neat little bevel, thusly:

Your hand will not slide easily up and over this abrupt shoulder. So,

just take that handy X-acto knife and cut in a neat little bevel, thusly:

It's not my finest work, but it gets the job done. I suppose I could

smooth the bevel some with sandpaper. Your hand will slide up over

this and onto the grip much easier now, and with less aggravation to your

hand

It's not my finest work, but it gets the job done. I suppose I could

smooth the bevel some with sandpaper. Your hand will slide up over

this and onto the grip much easier now, and with less aggravation to your

hand

As I mentioned, the return spring is too weak. It doesn't even have enough strength to lift the handle when the squeezer is held horizontally. This means that when you are squeezing rivets or dimples, especially with one hand, that it doesn't return as positively to your hand when you release the handle as the Tatco does. To test this, just hold the squeezer horizontally, with the fixed handle on the bottom and the moveable handle on top. Press the moveable handle all the way down, then release your hand slowly. The handle will barely rise, if at all. Here is a picture of the squeezer in the static position with the stock spring:

The closest match I could find for a stiffer spring was an Ajax brand #415 spring. It was plenty stiff; however, the thicker coils bottomed out too soon, so I had to cut it down. I cut a little bit at a time until the handles would just come together without the spring bottoming out. I ended up taking off 3.75 coils. It sure is a lot shorter than the original spring, but even as short as it is, it works better than the stock spring. Here are the 3 springs:

The one on the right is the original spring. The one on the left is

the Ajax #415, and the one in the middle is the cut-down Ajax.

The one on the right is the original spring. The one on the left is

the Ajax #415, and the one in the middle is the cut-down Ajax.

I cut 3.75 revolutions off one end of the spring, and I ground both ends as

flat as possible. Since the cut end of the cut-off spring is not wound

flat, all you can do is grind it as flat as possible. I also ground

the flat-wound end much flatter than it was, as evidenced in the top of this

picture.

I cut 3.75 revolutions off one end of the spring, and I ground both ends as

flat as possible. Since the cut end of the cut-off spring is not wound

flat, all you can do is grind it as flat as possible. I also ground

the flat-wound end much flatter than it was, as evidenced in the top of this

picture.

After the above mods, the moveable handle returns much better. This is a picture of the "static rest" position described above, this time with the modified spring installed:

The other problem I noticed with both the Avery and the Tatco was the length of the fixed handle. As with the spring situation, I particularly noticed this when sitting down, dimpling small parts with the squeezer in one hand and the part in the other hand, with the base of the fixed handle resting on my leg. When I squeezed the handles together, I had to be careful I didn't pinch the top of my leg between the 2 handles. To fix this, the fixed handle needs to be about an inch longer than the moveable handle. There are many ways you could make this mod, such as remove the grip and weld on a 1" piece or make an extension. The grips are not easily removable (a good feature compared to Tatco), and I have a metal lathe, so I decided the easiest way for me was to make an aluminum extension plug to go in the end of the fixed handle. You could do the same with wood if you have a wood lathe, or you could also just whittle a piece of dowel and shove it in the end of the handle.

First, you need to cut away the end of the grip, like this:

An Xacto knife works well for this. I used about a 45 degree angle

when I cut (not critical at all).

An Xacto knife works well for this. I used about a 45 degree angle

when I cut (not critical at all).

Then make a plug to go in the now-opened end of the fixed handle and extend the length of the handle by about an inch. Here is the aluminum piece I made on the lathe:

The only dimension that matters much is the narrow end that will go into the

handle; it needs to be a snug fit, so it will stay in there. The

internal and external portions should each be about an inch long, and the OD

of the external part should be about an inch; same as the OD of the grips.

The only dimension that matters much is the narrow end that will go into the

handle; it needs to be a snug fit, so it will stay in there. The

internal and external portions should each be about an inch long, and the OD

of the external part should be about an inch; same as the OD of the grips.

Here's what the extension looks like after I tapped it into place:

Here is the final modified Avery squeezer:

UPDATE: Did you notice what a fine job I did turning that aluminum on my lathe? I used a fresh, sharp bit, and gave it a beautiful satin finish. The problem with that turned out to be that it was a bit too slippery when placed on my leg. I had some of that rubbery dip coating around, whose color just happened to perfectly match the color of the grips, so I dipped the end of the fixed handle and extension into that a couple times. Works great now!

I wrote Avery Tools and offered them these design ideas for free. I could see on my web monitoring software that they looked at this page after getting the email, but they didn't even have enough courtesy to respond to my email. Same thing with another design HERE. Avery customer service sure isn't what it used to be.

see my other CUSTOMIZATIONS

BACK TO MY RV BUILDER'S HOME

BACK TO BRIAN'S HOME