Here

is the die I made to go in my Avery rivet squeezer. This one is for

6AWG.

Here

is the die I made to go in my Avery rivet squeezer. This one is for

6AWG.July, 2006 AVIONICS, ELECTRICS, & CONTROLS

July 1 - spent a bunch of time pondering how my wiring should go. I got the 6AWG wire from SteinAir, but I am not sure how things will be physically wired. Started studying wiring diagrams and making up my own wiring block diagrams of how I think it will get wired. 1.0 hr

July 2 - made a couple dies to use in my rivet squeezers for crimping #6 and #8 terminals. It seems dumb for people to buy a big, heavy, expensive crimper for these terminals when we already have most of one; our rivet squeezers. Make up list of all the electrical system components I'll need to order. 5.0 hr

Here

is the die I made to go in my Avery rivet squeezer. This one is for

6AWG.

Here

is the die I made to go in my Avery rivet squeezer. This one is for

6AWG.

The

results of my home-made crimper dies to go in the rivet squeezer.

Looks pretty good to me.

The

results of my home-made crimper dies to go in the rivet squeezer.

Looks pretty good to me.

This is

the result of the 8AWG crimping die I made for the rivet squeezer.

This is

the result of the 8AWG crimping die I made for the rivet squeezer.

July 4 - studying Perihelion Design drawings, and making up a list of questions to ask about it. Start making up block diagrams of how all the engine power management will work.

Click on any of these 3 drawings to see a larger version (best viewed in maximized window).

This is the original block wiring diagram I made, featuring the 3 main

components from Perihelion Design,

the Low Voltage And Aux Battery Management Module, the Over Voltage

Protection module, and the Power Schottky. The Power Schottky

ensures the E-bus gets power from either battery. The main

problem with this design is that it relies on the lower contactor to supply

power to the E-Bus. The biggest problem is that if the LVAABMM

disconnects Battery 2, and then I turn the bus master off before turning the

aux master to ON, then I just created a much bigger problem than losing the

alternator. Now I have to waste precious battery power trying to

restart the engine, when all I started with is an alternator problem.

Nope - this is not going to work.

This is the original block wiring diagram I made, featuring the 3 main

components from Perihelion Design,

the Low Voltage And Aux Battery Management Module, the Over Voltage

Protection module, and the Power Schottky. The Power Schottky

ensures the E-bus gets power from either battery. The main

problem with this design is that it relies on the lower contactor to supply

power to the E-Bus. The biggest problem is that if the LVAABMM

disconnects Battery 2, and then I turn the bus master off before turning the

aux master to ON, then I just created a much bigger problem than losing the

alternator. Now I have to waste precious battery power trying to

restart the engine, when all I started with is an alternator problem.

Nope - this is not going to work.

This is a block diagram of Wally Enga's schematic. It's the same as

above, except the second contactor is used to tie the Batt 2 line to the

alternator output, and the E-Bus is wired directly to Battery 2. I see

no need for the Power Schottky, though.

This is a block diagram of Wally Enga's schematic. It's the same as

above, except the second contactor is used to tie the Batt 2 line to the

alternator output, and the E-Bus is wired directly to Battery 2. I see

no need for the Power Schottky, though.

July 5 - talked to Eric at Perihelion about my questions about his components and how they will be used. Ordered switches and contactors from B&C. Spent a couple hours studying schematics. 2.5 hr

I spent quite a bit of time analyzing Bob Nuckolls' Z-19 schematic, and

converting it to a block diagram that is easier to understand. This is

my adapted version of it. I removed a couple things, like the

endurance bus and the alternate feed to that. Everything but critical

engine circuits will be on one main bus. I also added a couple things,

like making the primary and secondary E-Bus switches 3PDT or 4PDT instead of

DPDT, to accommodate separate fuel pumps on separate circuits, each fed by

either battery. I also added the same diode bridge scheme to power the

ECM memory from both busses. It looks like this will work well.

Like Wally's diagram, it uses the OVP and LVAABMM modules from

Perihelion Design, but not the

Power Schottky. This uses TWO E-busses, each wired direct to its own

battery. Then, through the use of diode bridges, each will separately

power the REALLY critical engine components; the fuel pumps and the ECM.

I spent quite a bit of time analyzing Bob Nuckolls' Z-19 schematic, and

converting it to a block diagram that is easier to understand. This is

my adapted version of it. I removed a couple things, like the

endurance bus and the alternate feed to that. Everything but critical

engine circuits will be on one main bus. I also added a couple things,

like making the primary and secondary E-Bus switches 3PDT or 4PDT instead of

DPDT, to accommodate separate fuel pumps on separate circuits, each fed by

either battery. I also added the same diode bridge scheme to power the

ECM memory from both busses. It looks like this will work well.

Like Wally's diagram, it uses the OVP and LVAABMM modules from

Perihelion Design, but not the

Power Schottky. This uses TWO E-busses, each wired direct to its own

battery. Then, through the use of diode bridges, each will separately

power the REALLY critical engine components; the fuel pumps and the ECM.

July 6 - studying schematics and working on my block diagram 2.5 hr

July 7 - Work on block diagram. Update web site 1.0 hr + 2.0 hr doc

July 8 - work on block diagram 1.0 hr

July 9 - work on block diagram, make up numerous questions for Aeroelectric and Eggenfellner lists. Work on studying schematics and switches layout. Wire up E-bus jumper wires. 4.25 hr

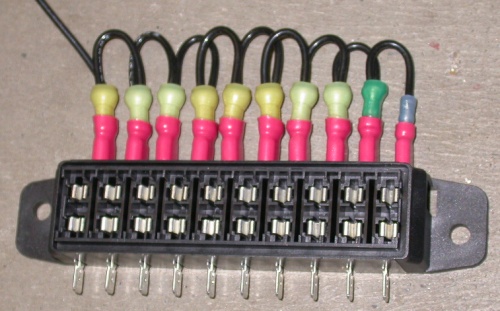

This

is the fuse block I got from Waytek. Instead of a common hot

terminal, each fuse is separately wired, so I had to order a couple

different sets of Faston connectors big enough to each hold 2 #14 wires.

Finally got ones I liked, and wired up the e-bus.

This

is the fuse block I got from Waytek. Instead of a common hot

terminal, each fuse is separately wired, so I had to order a couple

different sets of Faston connectors big enough to each hold 2 #14 wires.

Finally got ones I liked, and wired up the e-bus.

July 10 - placed ACS order and another B&C order. Pondering switches and meters and looking through electronics catalogs for switches. Asking questions on lists. 3.0 hr

July 11 - Received first B&C order. Starter switch is way too light. B&C says it's 5a and even that's too low. Grayhill site says it's 1a rated. Will return it. Placed onlinecomponents order and another Perihelion order for dimmers. Tried several CAD programs, including the new ver 12 of TurboCAD. Ended up liking the old ver 6.5 TurboCAD that had come in Bob Nuckolls' Aeroelectric CD. Works great and it was free. Spent lots of time all day doing switch and electric research. Study my wiring stuff and ground plate layout. 4.0 hr

July 12 - working on putting together Allied order, switches research, parts research, TurboCAD schematic. Worked to 0330 on TurboCAD. 8.0 hr

July 13 - went to auto parts store & perusing starter switches and relays. Work on TurboCAD schematics and study Allied catalog to finalize order. Suddenly realized that Gary's fuel auto-cutover switch and relay system are 2 serial single points of failure that could take out both fuel pumps. So, I won't need the switch & relay I just ordered from onlinecomponents. I decided it's better to just have 2 SPST switches on the panel; one for each pump, and control them manually. That was one of the few parts of the standard Eggenfellner wiring diagram I had planned to use, but now I think manual switches are better than the automatic cutover. Worked to 0300 again on TurboCAD schematics. 7.5 hr

July 14 - placed $500 Allied order for switches and other components. The 4PDT locking toggle switches are about $75 each! The mil-spec SPST locking toggles for the fuel pumps were about $40 each. Those locking toggles are quite expensive, but I think the locking toggles are the way to go. Also received my second B&C order for the diode bridges and heatsinks. They weren't padded at all, so the heatsinks beat up the diode bridge leads. Packed up B&C starter switch to return. Sorted out my existing switches, and worked some more on the TurboCAD schematics. 2.0 hr

July 15 - worked on TurboCAD schematics until 0400! Once, I get started, it's hard to stop. 6.0 hr

July 16 - clean up , organize things. Work on physical layout of contactors and diode bridges. The heatskinks are HUGE and take up lots of space. I am sonsidering doubling up the diode bridges on them. While pondering all this, I realized that any one diode bridge is a critical Single Point Of Failure for both pumps. If one diode shorts and heats up & takes the other diode in the bridge out with it, I am screwed, especially on the ECM circuit, as there is only one, while the fuel pumps have two. Also, as I am doing my circuits layout in TurboCAD, I am realizing that I will have to either double up on circuits or add another fuse block. 2.25 hr

The heatsinks for the diode bridges are HUGE and take up a LOT of space.

Looking for a better solution.

The heatsinks for the diode bridges are HUGE and take up a LOT of space.

Looking for a better solution.

Diode bridges were packed loose, so they arrived from B&C all banged up.

B&C took them all back with no problems.

Diode bridges were packed loose, so they arrived from B&C all banged up.

B&C took them all back with no problems.

July 17 - Received both Perihelion orders Spent several hours doing alternate ECM wiring schematics and writing email to Eric at Perihelion about it. Look over Perihelion parts, look up components in catalogs. Work to 0400 again on schematics, changing all the diode bridges to Eric's Power Schottky diodes, laid out in pairs as 2:1 bridges. Getting up in the morning to go to work is hell after nights like this. 8.0 hr

July 18 - worked on schematics 2.0 hr

July 19 - received onlinecomponents order. Unfortunately, I no longer need that switch specified in Gary's schematic for the pumps control. Packed up diode bridges to send back to B&C. Packed up Schottky diode to send back to Perihelion. Will use 8 non-heatsinked Schottky diodes instead of the one heatsinked one. Work on schematic to 0300. 3.0 hr

July 20 - received Allied order. Examine, organize, put away Allied order. I also got a selection of super bright large LEDs in that order, so I plan to add them to some cabin lighting. Work on schematic more. 2.5 hr

Here are a couple of the locking mil-spec switches I ordered from Allied.

Very expensive! But I think they'll be worth it.

Here are a couple of the locking mil-spec switches I ordered from Allied.

Very expensive! But I think they'll be worth it.

nice little signal-powered digital volt meter from

Allied.

nice little signal-powered digital volt meter from

Allied.

July 21 - received LEDtronics order for LED-based 1156 bulbs for my cargo lighting. One is cracked. Emailed LEDtronics, and they will send me a new one. The LED ones are not as bright, and definitely not as broad a light, as the incandescent ones, but these will work great with Perihelion's dimmer switches. 1.0 hr

Jul 23 - trying to find a place where I can install a THIRD 12-circuit fuse block, to handle all the additional circuits. Finally found a place on the LT side, if I move one of the existing ones. 2.0 hr

July 26 - Found fuse blocks at B&C that are smaller than the ones I got from SteinAir. I may get those, but I also need to put together an order for connectors at the same time, and everyone's away at AirVenture this week. Work on schematics, update web site 1.0 hr + 3.0 hr doc

Jul 28 - exchange emails with Eric about schematics and with B&C about getting a DB37 connector. I need a male DB37 connector for the BMA EFIS, yet no one seems to carry them. Not B&C, not SteinAir. Work all evening getting this web site at least basically up to date for the last several weeks. I don't have many new pics to add, but I will work on that next week. 1.0 hr + 4.0 hr doc

July 30 - measure fuseblocks and compare B&C and SteinAir blocks, to see what will fit best. Looking up DB connectors in DigiKey catalog. 1.25 hr

July 31 - placed Allied order for DB connectors and pins. It took a long time to find the right ones in the huge selections in all the catalogs. Placed SteinAir order for another fuse block and some other small stuff.

go to AUGUST, 2006 avionics

BACK TO MY RV BUILDER'S HOME

BACK TO BRIAN'S HOME