Fuel shutoff

valve, ready to start mating to modified plate. Nice quality valve,

incredibly expensive (>$600)

Fuel shutoff

valve, ready to start mating to modified plate. Nice quality valve,

incredibly expensive (>$600)November, 2003 fuselage work

Nov 6 - Just got back from a gig in the UK. Install brake feed lines with new dual brake system. Mount new Andair 6-way fuel valve to mount plate. 2.5 hr

Fuel shutoff

valve, ready to start mating to modified plate. Nice quality valve,

incredibly expensive (>$600)

Fuel shutoff

valve, ready to start mating to modified plate. Nice quality valve,

incredibly expensive (>$600)

Fuel

valve, mounted to plate.

Fuel

valve, mounted to plate.

Nov 7 - Remove brake fluid feed lines and redo them a bit longer, for better fit. Look into using Aeroquip lines instead of what looks like an awful job getting the 5/16" fuel return lines and new 3/8" fuel supply lines in place. Decided against it due to MUCH higher cost and weight of Aeroquip lines, compared to solid aluminum lines. Install fuel valve and work on hooking up 3/8" pressure lines, by modifying bends in existing lines (that were there for old Van's 3-way valve). 4.5 hr

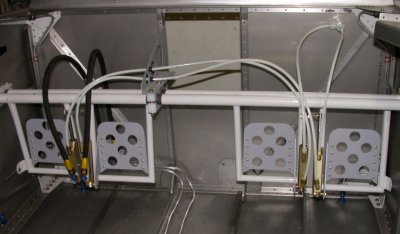

I

finally got the brake fluid supply lines redone to my satisfaction.

I

finally got the brake fluid supply lines redone to my satisfaction.

Nov 8 - Working on fuel lines to shutoff valve. 1.0 hr

The Andair shutoff valve has removable fittings, so you can screw the AN

fittings into them, then just bolt them straight on to the valve. It's

a nice design, although I am not very impressed with their poor

responsiveness to my emails to them about a missing screw. I sent them

3 emails about it, and they never did respond. I emailed Eggenfellner,

and he sent me a new screw.

The Andair shutoff valve has removable fittings, so you can screw the AN

fittings into them, then just bolt them straight on to the valve. It's

a nice design, although I am not very impressed with their poor

responsiveness to my emails to them about a missing screw. I sent them

3 emails about it, and they never did respond. I emailed Eggenfellner,

and he sent me a new screw.

Nov 10 - second visit from Frank Stites, EAA 740 Technical Counselor 2.0 hr

Nov 12 - Working on fuel lines to shutoff valve. Removed RT brake line to redo it later after new fuel plumbing. My friend, Jim DeHaven, an A&P, stopped by to look at some imperfections in my fuel line plumbing for me. I had a crease and a slightly pinched curve that I wasn't sure about. Jim ended up saying I should replace that line, so after he left, I removed the LT fuel line and the LT brake line. 4.0 hr

I

ripped everything out, except one 3/8 fuel supply line. The supply

lines were quite difficult to get in, so I really did not want to have to

redo any more than I had to. The problem with this configuration is

that Gary Newsted's Eggenfellner manual recommends putting the fuel supply

lines on the TOP set of bushings, not the bottom, but I think I can make

this work OK, without having to remove that 3/8" fuel supply line I

worked so hard to get into the original Van's design lower position.

I

ripped everything out, except one 3/8 fuel supply line. The supply

lines were quite difficult to get in, so I really did not want to have to

redo any more than I had to. The problem with this configuration is

that Gary Newsted's Eggenfellner manual recommends putting the fuel supply

lines on the TOP set of bushings, not the bottom, but I think I can make

this work OK, without having to remove that 3/8" fuel supply line I

worked so hard to get into the original Van's design lower position.

My pile

of removed plumbing lines.

My pile

of removed plumbing lines.

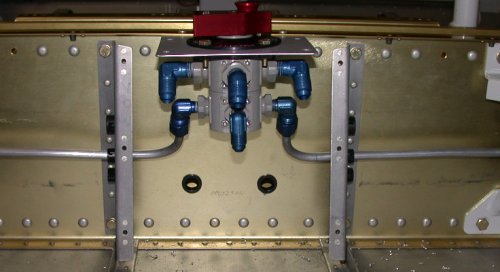

Here is the Andair fuel shutoff valve, with all but one of the AN fittings

installed. I decided to use a 45 degree fitting for the fuel supply

output, so that's on order from Van's. After ordering and receiving

the 45 degree fitting, I ended up going back to a 90, anyway. I

installed it at a bit of an angle, not facing straight down, as the return

fitting is here. This is so it would clear the return fitting.

Here is the Andair fuel shutoff valve, with all but one of the AN fittings

installed. I decided to use a 45 degree fitting for the fuel supply

output, so that's on order from Van's. After ordering and receiving

the 45 degree fitting, I ended up going back to a 90, anyway. I

installed it at a bit of an angle, not facing straight down, as the return

fitting is here. This is so it would clear the return fitting.

Nov 13 - Made 2 attempts to install LT fuel line. Both failed, due to dents or creases put into the line by the bender. It's especially hard to put in multiple bends close together without the bender dinging up the tubing. Modified the bender so it won't dent the line (see pic & description). Ran out of tubing, so while I wait for ACS order to come in, switched over to working on landing light lenses. 4.0 hr

The

pile of scrapped fuel supply, fuel return, and brake lines continues to

grow.

The

pile of scrapped fuel supply, fuel return, and brake lines continues to

grow.

Nov 16 - Finished with landing light wiring (for now, until I get more wire and terminals). Went back to what fuel line plumbing I can do while waiting for my plumbing parts to come in from Aircraft Spruce. Studied Dan Checkoway's web site to see how his fuselage/tanks/fuel lines came together. Decided to do my return line different from that shown on Gary Newsted's Eggenfellner manual. I am putting the return line into the tank itself, rather than the tank cover. That way, I won't have to screw around with the return line if I ever need to remove the fuel tank cover. Finished putting the return lines and fittings into the tanks. Install return line bulkhead fittings into fuselage. I need to order a bunch of parts from Van's tomorrow, to complete both my plumbing and wing wiring. Plus I have an order for plumbing parts coming in from ACS on Tue. 8.0 hr + 3.0 doc

Installed fuel return line bushing in second rib in each tank.

Installed fuel return line bushing in second rib in each tank.

Here

are the fuel return lines that go in each tank, between the AN fitting on

the outside rib and through the second rib in.

Here

are the fuel return lines that go in each tank, between the AN fitting on

the outside rib and through the second rib in.

Here is the fuel return line installed. I used straight AN fittings

here, but later decided to change them for 90 degree fittings.

Here is the fuel return line installed. I used straight AN fittings

here, but later decided to change them for 90 degree fittings.

This is the tank with the 5/16" 90 degree AN fitting installed. I

need more of these, as I'll use a 90 on the fuselage, too, so more are on

order from ACS.

This is the tank with the 5/16" 90 degree AN fitting installed. I

need more of these, as I'll use a 90 on the fuselage, too, so more are on

order from ACS.

Here

is the 5/16" fuel return line 90 degree AN fitting on the outside of

the fuselage. Fwd is to the LT in this picture. This 90 and the

90 on the tank face each other, so they should go together well when the

wing goes on. It's a nice straight line from the fuel valve, straight

through the middle hole in the landing gear weldment, to the other end of

this AN fitting.

Here

is the 5/16" fuel return line 90 degree AN fitting on the outside of

the fuselage. Fwd is to the LT in this picture. This 90 and the

90 on the tank face each other, so they should go together well when the

wing goes on. It's a nice straight line from the fuel valve, straight

through the middle hole in the landing gear weldment, to the other end of

this AN fitting.

Nov 17 - Trying to catch up with updating web site, deciding on seats, putting parts orders together 5.0 hr

Nov 18 - Received my ACS order with more tubing and plumbing parts, so I resumed work on the fuel valve plumbing. Put the LT fuel supply line in with no problems. Found that there is NO WAY I am going to get the 5/16" fuel return lines in with this line routing configuration, though. Tore out ALL the plumbing, and reconfigured the brackets and snap bushings so it's fuel supply on top, then fuel return, then brake line on the bottom, as recommended in Gary Newsted's manual, and as I should have taken the trouble to do in the first damn place. The pile of removed plumbing lines is even bigger now. 7.0 hr

Nov 20 - Working in Boston. Slow evening, so I took some personal time out to get web site up to date. 3.0 hr

Nov 24 - update web site - work on index, tools pages 2.0 hr

Nov 25 - update web site - work on index. Look into ordering seat belts and ELT. 4.0 hr

Nov 26 - My first attempt at redoing the RT fuel return line was 7/8" too long. Removed it & made a shorter one. Install LT & RT fuel return lines. Finally got it done to my satisfaction. Worked on fuel supply lines layout, but decided to wait until wings are mounted, to make sure where they will come out and how long they need to be. 5.0 hr

Started over from scratch with all cabin plumbing. Started the redo

with the 5/16" return lines. First, I had to thread it through

the bushings, then flare the other end.

Started over from scratch with all cabin plumbing. Started the redo

with the 5/16" return lines. First, I had to thread it through

the bushings, then flare the other end.

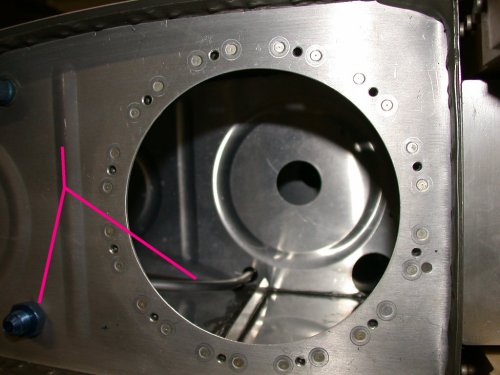

Got the 2 return lines in nicely. They make a straight run from here

to bulkhead fittings at the side of the fuselage. Configuration shown

here is to angle the return fittings aft at 45 degrees and the supply

fitting fwd at 45 degrees, so they don't interfere with each other. I

later decided I think I can make the 90 degree curve in the supply lines

close enough to the end flare that I can angle them both back at about 45

degrees. I make the 90 degree end bends in the tubing first, then feed

them from the center out.

Got the 2 return lines in nicely. They make a straight run from here

to bulkhead fittings at the side of the fuselage. Configuration shown

here is to angle the return fittings aft at 45 degrees and the supply

fitting fwd at 45 degrees, so they don't interfere with each other. I

later decided I think I can make the 90 degree curve in the supply lines

close enough to the end flare that I can angle them both back at about 45

degrees. I make the 90 degree end bends in the tubing first, then feed

them from the center out.

Nov 27 - Work on fuel shutoff valve to firewall plumbing. Send emails to Van's and Eggenfellner list about whether or not to use F-601K-1 firewall recess with the Eggenfellner engine. The consensus was YES. Happy Thanksgiving! 1.0 hr NOTE - I later found out this was a very BAD idea. I strongly recommend using a flat plate over the firewall recess hole when using an Eggenfellner engine, especially if you're installing the heater.

Nov 28 - Continue installing fuel supply and return lines between fuel shutoff valve and firewall. 3.0 hr

Nov 29 - Still working on fuel supply line between shutoff valve and firewall. Got one made, but then the bender dented it, so I removed it and remade it. Modified bender further to prevent more denting. Finally got it in satisfactorily and started on return line. 4.0 hr

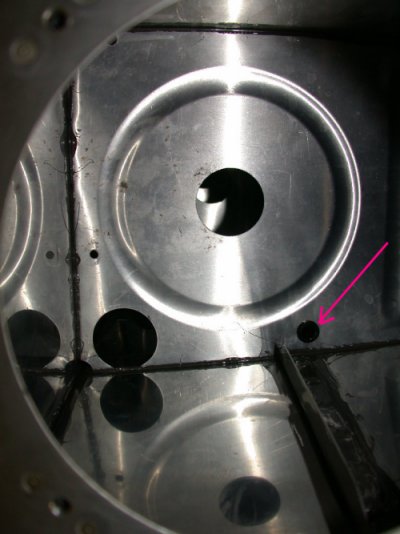

The edges

shown here also need to be radiused and polished, or you can get denting and

scratching.

The edges

shown here also need to be radiused and polished, or you can get denting and

scratching.

Nov 30 - Resume plumbing the fuel return line from the shutoff valve to the firewall. Finally got it done to my satisfaction. Then I found out that the F-601K-1 is not going to fit at all now, with the way I ran my return line. Grrrr! I hate to mess around with that return line, after I finally got it just right, but I'll have to either do that or use a flat plate where the F-601K-1 goes in the hole in the firewall. Start putting in new brake lines. Got the LT line half in, with some scratches that I was able to polish out. I spent lots of time relieving the stress in the lines, so they lay naturally in the correct position at the fittings. 3.5 hr

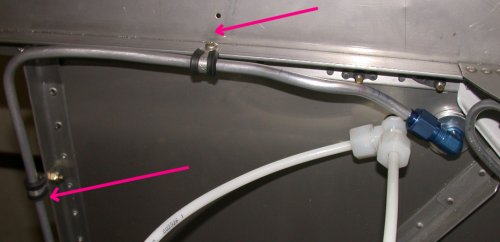

Got the return line finished between the shutoff valve and the

firewall. After I was done, I realized the spot I'd chosen for the

upper Adel clamp was going to be right in the way of the sub-panel support

rib, so I moved it over an inch. I also found out that the F-601K-1

firewall recess was not going to clear the tubing, so that was another

problem.

Got the return line finished between the shutoff valve and the

firewall. After I was done, I realized the spot I'd chosen for the

upper Adel clamp was going to be right in the way of the sub-panel support

rib, so I moved it over an inch. I also found out that the F-601K-1

firewall recess was not going to clear the tubing, so that was another

problem.

Here is the

LT brake line partially reinstalled. Working with 1/4" tubing

sure is nice after working with the 5/16" and especially the

3/8". The fuel supply line runs up the LT side and the fuel

return line is on the RT. Looks like it's time to vacuum out the

cabin. I don't get in there; I just work from the outside and lean

over the top.

Here is the

LT brake line partially reinstalled. Working with 1/4" tubing

sure is nice after working with the 5/16" and especially the

3/8". The fuel supply line runs up the LT side and the fuel

return line is on the RT. Looks like it's time to vacuum out the

cabin. I don't get in there; I just work from the outside and lean

over the top.

GO TO DECEMBER

BACK TO MY RV BUILDER'S HOME

BACK TO BRIAN'S HOME