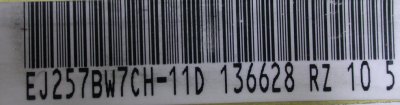

pic of the engine ID sticker

pic of the engine ID stickerENGINE WORK February, 2008

Feb 1 - Eggenfellner published a highly slanted version of the STi fiasco on his mail list and on VAF. It's the old technique of attacking and discrediting the messenger when you can't refute the message. In addition to his usual strategy of blaming all the problems on the shortcomings of his customers, he also claims that the STi was "highly experimental" and that all STi customers were made aware of this before purchasing. He claims that it's only a couple STi customers who are unhappy. BS. See here, here, and here, just for starters. He also puts quite a spin on the history of the PSRUs. We remaining STi victims ignore Eggenfellner's posturing, and just keep working toward getting all the issues sorted out. Several of us are now working among ourselves on getting the new supercharger pulley we need to keep the supercharger from overspeeding.

Feb 4 - remove PSRU temperature sensor plug and install sensor. Extend temp sensor lead wire to new sensor location. FYI - sensor is VDO 81/97 3.04 6-24v. 0.5 hr

Feb 18 - I've been exchanging daily emails with other STi users, sorting out our remaining issues. No actual work on plane, tho. :-(

Feb 20 - Looking into using my ECUTEK software & hardware, and digging up old ID info my my engine and ECU. The ECUTEK software needs to know exactly what ECU I have. Eggenfellner had been most evasive & unhelpful back in January and July, '05 when I was trying to identify exactly what model, year, and market engine & ECU he'd sent me. On several occasions, he told me I had a certain model, year, market combination, only to find out later no such combination, so I'd ask him again & get a new answer. We went through that several times. I ended up getting no useful info from Eggenfellner and some info from a Subaru dealer. I think he was just getting the engines randomly, wherever he could find one, so there's no continuity among the STi customer as to what we got. As far as I could tell back then, I ended up with what is probably a 2004 US market STi engine and a 2004 US market Forester ECU. Spent some time researching and re-documenting the numbers I have on my engine. Also reinstalled & updated my ECUTEK software. Also checked that I have a #4 stamped on my new PSRU, indicating that it has the latest improvements to the Gen 3 PSRU. Early Gen 3 PSRU customers were having to return them, sometimes multiple times, for front oil seals leaks. 1.0 hr

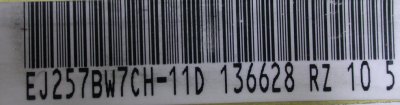

This is the engine ID info I have:

on bar code sticker: EJ257BW7CH-11D 136628 R2 10 5 I was told by a Subaru dealer that 7CH or 5CB at the end means "STi" and TBB or SBB means "Forester"

stamped on bellhousing: C136628

engraved on bellhousing: 586738585293 Probably an Eggenfellner-created serial number

stamped on LT (as in car) intake pad: B604642

stamped on RT (as in car) intake pad: C019041

the most likely of several numbers printed on sticker on ECU: 22611AJ471 I think the AJ471 are the key numbers

pic of the engine ID sticker

pic of the engine ID sticker

pic of

all the mysterious numbers on the ECU

pic of

all the mysterious numbers on the ECU

Randy Crothers announced that, as part of his STi engine teardown to fix the VVT cam angle problem, he's found his intake manifold was leaking. The machined mating surface was not flat. Pretty ironic, considering that Eggenfellner's business began as a provider of intake manifolds for Subaru engines, and the poor installation comes as no surprise, given my experience with some of Eggenfellner's work quality. This might also help to explain some of Randy's extremely difficult cold starting problems.

Feb 21 - assemble engine hoist frame 0.25 hr

Feb 22 - Allan Christer, unhappy Eggenfellner H6 owner and originator of the H6 Orphans Yahoo Group, crashed his plane. Allan had experienced lots of problems with his H6, including starting, cooling, and wiring/ECU problems. I believe Allan had replaced his ECU & harness after experiencing lots of problems with what came from Eggenfellner, and he wasn't getting solutions from Eggenfellner. Details are sketchy now, but I understand the crash was shortly after replacing his ECU & wiring harness with the one made by Robert Paisley. Eggenfellner immediately issued a rather vehement statement claiming the engine was no longer an "Eggenfellner" engine, denying any responsibility, and blaming all problems on Allan. I understand Allan is OK, but the plane isn't. I don't think the crash, and especially the statements from Eggenfellner about the ECU, are going to help Robert Paisley's alternate ECU business much. And I don't think I'll be holding my breath on Robert ever actually producing an ECU for the STi.

Feb 23 - I've heard in the past from several sources that the type of supercharger Eggenfellner chose for this engine is all wrong. Here is some info Randy Crothers got from a supercharging expert:

I just got off the phone from talking to a guy that runs PSE Superchargers. He overhauls the things for a living and has done so for along time. When I finally explained to him just how I have been using this supercharger he could not believe it. The application is wrong in many ways. I will attempt to hit most of the points from the conversation below.

The M45 is too small for the STI engine. It is more appropriate for a Mazda Miata.

The 14,000 rpm redline is only for very short durations only, not meant to be anything near continuous. And we're now running it at over 16,000 rpm with the Gen 3 PSRU! He recommended going no higher than 12,000 rpm continuous.

The way we have it configured, the supercharger is always working very hard, whether the waste gate is open or not. This is because it is always working with a pressure differential and it is pulling and pushing air, waste gate open or closed.

The waste gate should be redirecting the air up in front of the supercharger, recycling it back through in a loop, not just dumping it out into the cowling. That way the supercharger can spin freely without a load when boost is not required. The way we have it, the supercharger is always working very hard. He said this will shorten the life considerably.

Cog belt drives will kill these superchargers. The vibrations from the cog belt will take out the bearing in the nose. He estimated a life span at around 50 hours with a cog belt.

For the STI engine we should be using an M62 supercharger in the following manner. To get enough air from the M45 will work it too hard all the time.

He said this is the configuration the superchargers are designed to work with.

Air Filter, straight run of tubing with the MAF sensor in it, Throttle Body, then tubing to the supercharger inlet, the outlet needs to be the same size as the throttle body and likewise for the tubing to the intercooler. After the intercooler there should be a "bypass valve", what we have been calling the waste gate valve. It should direct un-needed air back to the tube in front of the supercharger inlet, and in front of the MAF. It should have a 6 rib serpentine drive belt.

He said that the seals in a throttle body are designed for suction sealing. They may tend to blow out when pressurized.

He could not believe how wrong the installation is as we are using it.

Feb 24 - finish assembling engine hoist frame. Hoisted engine/nose. Removed front wheel and fork. Started threading nose gear leg. It was easy at first, but got harder toward the end. 2.5 hr

Feb 27 - cranked on the gear leg threading die awhile 0.25 hr

go to MARCH engine

BACK TO MY RV BUILDER'S HOME

BACK TO BRIAN'S HOME