This is one from of the stock radiators that we had to

pay Eggenfellner to rework way back shortly

after we got the engines. And a mighty fine job they

did! Talk about a cold weld!

This is one from of the stock radiators that we had to

pay Eggenfellner to rework way back shortly

after we got the engines. And a mighty fine job they

did! Talk about a cold weld!ENGINE WORK November, 2008

Nov 6 - remove LT radiator, start looking at what will fit for a larger replacement. Work on radiator layout and mockups with blocks of 2" styrofoam blueboard. Emailed several questions to other STi people. Existing radiator cores are 3 5/8" x 5.5" x 7" thick. Ralph's are 2.5" x 7 x 9 cores with 1.5" tanks. John's are 3" x 8.5 x 9.5 cores with 1" tanks. 3.5 hr

This is one from of the stock radiators that we had to

pay Eggenfellner to rework way back shortly

after we got the engines. And a mighty fine job they

did! Talk about a cold weld!

This is one from of the stock radiators that we had to

pay Eggenfellner to rework way back shortly

after we got the engines. And a mighty fine job they

did! Talk about a cold weld!

Here's the LT radiator removed. I'm planning to see what size new

larger radiator I can fit in here. Ross Farnham has used a third

radiator in the rear. I may consider that. Ralph uses a third

radiator on the firewall, although I don't yet have details of his

installation.

Here's the LT radiator removed. I'm planning to see what size new

larger radiator I can fit in here. Ross Farnham has used a third

radiator in the rear. I may consider that. Ralph uses a third

radiator on the firewall, although I don't yet have details of his

installation.

Nov 12 - been kinda distracted since the election & been on a guns & ammo buying spree, as is apparently all of America. The rest of the economy may not be doing well, but guns and ammo are selling in record numbers, especially all the things we learned from the Klinton bans that will be the first to be banned under Obama. Every gun shop in the US is super busy from the minute they open until they close. One gun shop owner told me he'd sold more "black guns" in the 4 days since the election than in the previous 4 MONTHS. In the hour I was in his shop, I saw 2 ARs and an AK, plus lots of other stuff, get sold. Every gun & ammo supplier I know of is sold out. One major ammo supplier suspended new orders because he was 4,000 orders behind in the week since the election. Almost 60 million people did NOT vote for Obama, and now they're all out buying stuff we all know Obama & his pals will try to ban. See my new Obama page.

Nov 14 - gosh - half the month's gone already! Removed RT radiator and worked on layout with styrofoam blocks for new radiators. 2.0 hr

Nov 19 - primed & painted the rewelded supercharger mount bracket. 0.5 hr

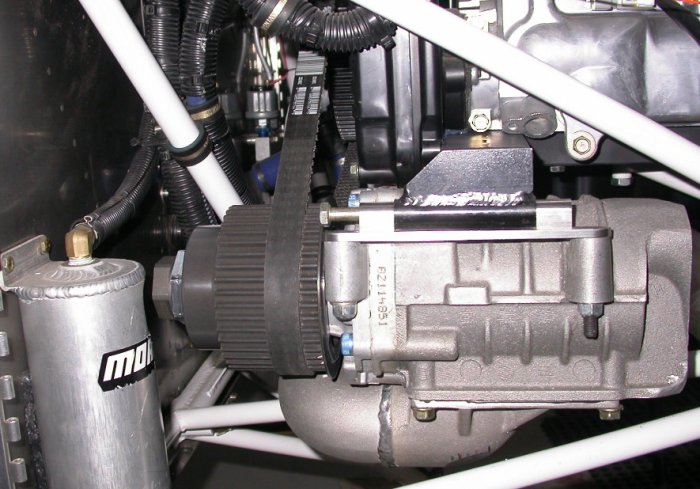

Nov 20 - reinstalled supercharger mount bracket. Fitted supercharger & related components back together. As before, I can just barely get the alternator belt on, and it barely clears the crank pulley. If I ever have the alternator off, I plan to grind the top of the engine a bit more, for some more clearance to make the alternator belt easier to install. I SURE won't be grinding on the ALTERNATOR for clearance, as Eggenfellner did on some of the other STi customers' engines! The supercharger belt is even tighter to get on. I really should have cut some more from the supercharger bracket arm; at least 1/8", maybe 1/4". The new supercharger pulley, aside from being WAY too thick and heavy, also has considerably longer teeth than needed, which also makes it harder to get that belt on. The nose of the SC pulley just barely clears the Moroso overflow bottle, so I took a ballpeen hammer and made a clearance dent in the bottle, both for more running clearance, and so i can get the belt onto the SC pulley through the gap. 2.5 hr

Another example of Eggenfellner's fine work. Subaru went to great

lengths to make sure the cam belt cover is completely sealed with rubber

gaskets, then Eggenfellner just ground a hole in it to make room for the

supercharger bracket. When I reinstalled the supercharger bracket, I

put RTV silicone sealer on the SC bracket where it goes up against this hole

in the case, to seal the hole.

Another example of Eggenfellner's fine work. Subaru went to great

lengths to make sure the cam belt cover is completely sealed with rubber

gaskets, then Eggenfellner just ground a hole in it to make room for the

supercharger bracket. When I reinstalled the supercharger bracket, I

put RTV silicone sealer on the SC bracket where it goes up against this hole

in the case, to seal the hole.

Nov 21 - more fitting of SC to new bracket and carefully grinding more clearance between the top of the supercharger and the bottom of the cam belt case (without actually grinding through either), so I can get the belt on. After many grind-and-fit iterations, I can get the SC to swing inboard just enough to get the SC belt on without too much trouble. 1.5 hr

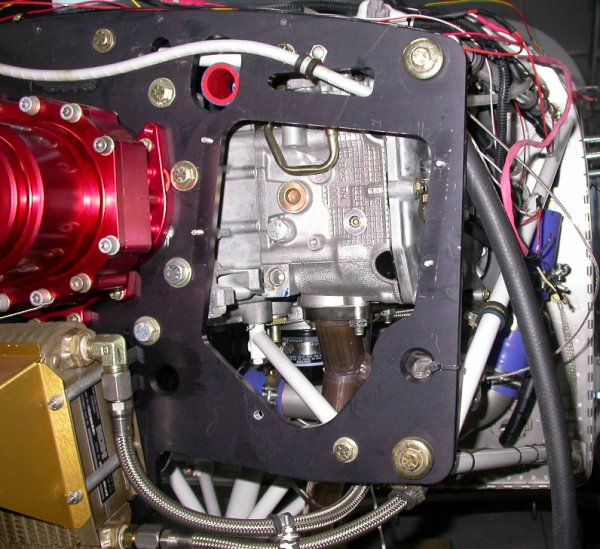

Here is the supercharger, with new pulley, temporarily reinstalled.

You can see the dent I had to put in the Moroso overflow bottle to clear the

big nut for the Trantorque bushing and so I can push the SC belt through

that gap to install the belt without having to remove the supercharger.

The SC pulley really didn't need to be this wide. I still may get it

redone in a shorter and much lighter version. As far as I can tell so

far, without actually running the engine, the SC belt tracking appears to be

unchanged. With the new shorter SC mount bracket, I now have more

clearance between the flat spot

I filed on the

bottom of the SC and the engine frame; before it was only about 1/6"

when the belt was tightened. The SC also now will protrude less far

out from the engine frame, hopefully reducing the need for a "supercharger

bump" that some other STi customers had to put in their cowl to clear the

supercharger.

Here is the supercharger, with new pulley, temporarily reinstalled.

You can see the dent I had to put in the Moroso overflow bottle to clear the

big nut for the Trantorque bushing and so I can push the SC belt through

that gap to install the belt without having to remove the supercharger.

The SC pulley really didn't need to be this wide. I still may get it

redone in a shorter and much lighter version. As far as I can tell so

far, without actually running the engine, the SC belt tracking appears to be

unchanged. With the new shorter SC mount bracket, I now have more

clearance between the flat spot

I filed on the

bottom of the SC and the engine frame; before it was only about 1/6"

when the belt was tightened. The SC also now will protrude less far

out from the engine frame, hopefully reducing the need for a "supercharger

bump" that some other STi customers had to put in their cowl to clear the

supercharger.

Nov 24 - David Domeier has swapped his H6 for a Lycoming. He reports the following weight observations:

My airplane with the H6 came in at 1256 pounds

with an empty CG of 77.33 one year ago. That included 8 pounds of ballast

at the HS.

Yesterday my airplane came in at 1073 pounds with an empty CG of 80.86.

This is with the Barrett “light weight” IO360 180 HP (187 on the dyno) and

a fixed pitch 3 blade Catto prop.

The really big difference is the weight on the nose gear. It was 364

pounds, it is now 244. Even at that, it appears I do not have to install

any ballast forward as the spread sheet shows the airplane within limits

with typical fuel loading the way I fly it. I need to do more calculating

with baggage on board.

The Subaru has many good features, but weight is not one of them. Major

weight reduction items removed from the start are the extra battery, 14

pounds, and ballast at 8 pounds. Another major item is GEN 3, it weighs 46

pounds, the older versions weighed 34 pounds. At one point when I was

installing the H6, as I recall, it weighed 394 pounds without the prop.

That was with radiators. As Jan has stated, this is in the range of an

IO360 angle valve 200 HP with all the stuff for a constant speed prop. I

do know the Hartzel prop comes at about 55 pounds. The Catto weighs 12

pounds plus bolts and extension for a total of about 20 pounds.

Nov 25 - removed supercharger & SC pulley so I can do some machining on the pulley. I need to take 0.071" from the inside of the snout length and I want to remove a lot of the excess wall thickness. Resumed wiring SDS ECU. 2.5 hr

Nov 26 - more SDS ECU & PLX wiring 1.5 hr

Nov 27 - machining inside of SC pulley, to remove excess material 2.5 hr

Nov 28 - more machining inside of SC pulley 1.0 hr

go to December, 2008 engine

BACK TO MY RV BUILDER'S HOME

BACK TO BRIAN'S HOME